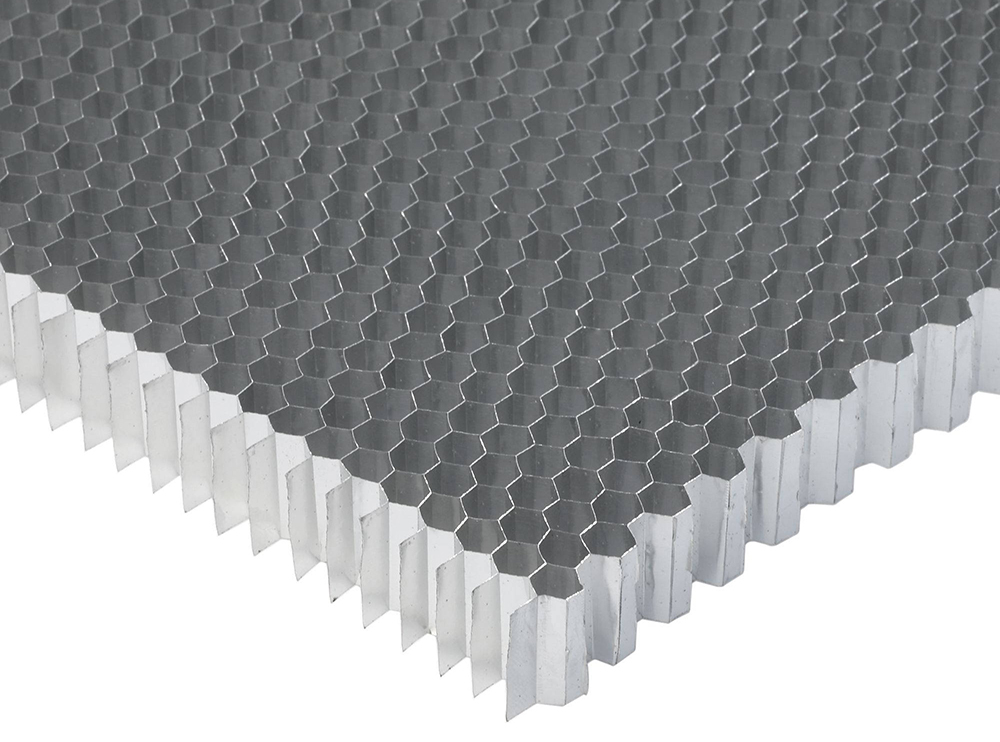

Aluminum Honeycomb Panels

Aluminum Honeycomb

Aluminium honeycomb is used extensively in the motorsport, marine and aerospace industries

Aluminium honeycomb core is one of the most widely used high performance honeycomb materials; chosen for its excellent strength to weight ratio (the best of all core materials) and bonding characteristics.

Aluminium honeycomb is used extensively in the motorsport, marine and aerospace industries and increasing now in construction industry where reducing weight whilst maintaining or improving the strength of a composite is of key importance.

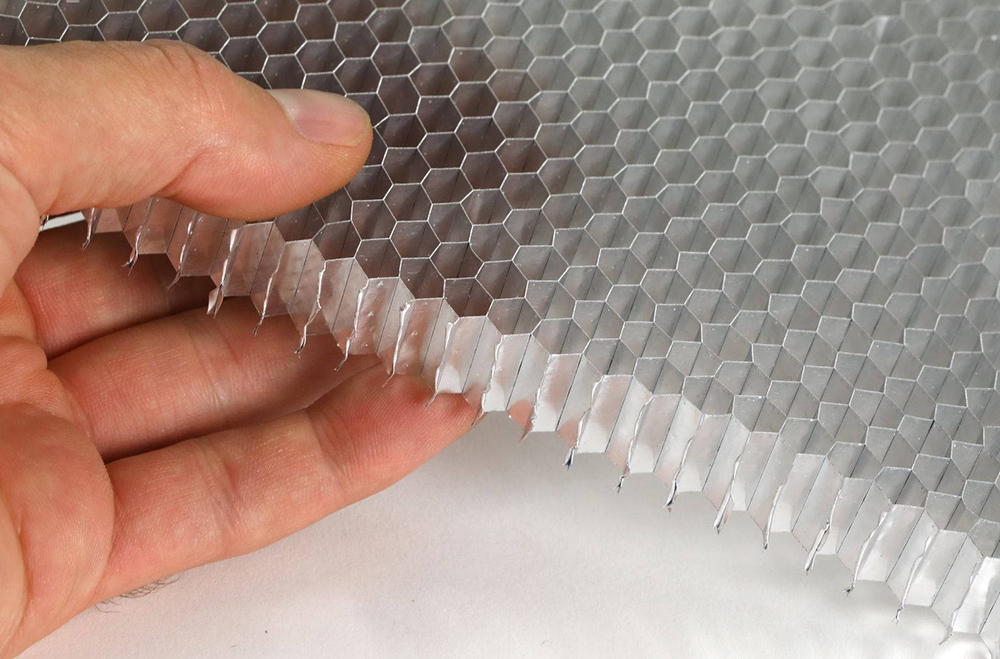

In its un-expanded (block) form aluminium honeycomb is also very compact and easy to ship cost effectively and without risk of damage. Un-expanded blocks can be easily expanded into their full sheet form without the need for sophisticated equipment.

Like all core materials aluminium honeycomb is designed to be sandwiched between two skins of material to create a sandwich panel. By creating distance between the two skins and ensuring that these skins cannot move relative to each other great mechanical advantage is gained making for very stiff panels with only minimal increase in weight.

Aluminum Honeycomb is a hexagonal core product

The aluminum honeycomb is light, resistant to compression and cuts, has excellent fire reaction (incombustibility) performaces and resists to corrosion, mould and it is recyclable.

Aluminum Honeycomb Applications

As core material, aluminium honeycomb is used in sandwich panels and it is utilised in: floors, roofs, doors, partitions, facades, working surfaces for automatic machines, laser jet cutting and for all products which require an optimal stiffness-to-weight-ratio.

Aluminium honeycomb is used for several of applications (i.e. for tool machines, for serigraphy..etc.) and in different sectors such as: public transport industry,nautical sector, building industry, etc… It is used as deflector for laminar flow-ventilation, and as crash-absorber for kinetic energy.

Aluminium honeycomb as panels’ core has several advantages:

lightweight

stiffness

good fire reaction

compression, shear and corrosion resistance

flatness

Thickness of non-expanded Blocks: 1000mm standard, the diameter of the cells from 3 to 25 mm. The density of the honeycomb depends on the thickness of the foil and the diameter of the cells.

Thickness of expanded section from 3mm to 60 / 200mm approx. (depending on the cell diameter).

Honeycomb density (from 20 to 163 kg/m3) depends on foil’s thickness and on cell size.

Buy aluminium honeycomb choosing from our range of cell sizes